Growth of 5-Axis & Multi-Axis CNC Machines

CNC machining is evolving rapidly, driven by automation, multi-axis machining, hybrid manufacturing, and sustainability. As we move into 2025, manufacturers must adopt these trends to stay ahead.

- Growth of 5-Axis & Multi-Axis CNC Machines Traditional 3-axis machines are being replaced by 5-axis and multi-axis CNCs for higher precision and reduced setup time. Why Multi-Axis CNC is the Future?

- Better surface finish & accuracy

- Faster production with reduced repositioning

- Ideal for aerospace, automotive, and medical industries

- CNC Automation & Lights-Out Manufacturing Fully autonomous machining with robotic automation, real-time monitoring, and IoT-enabled smart machines is the future. Key Benefits:

- 24/7 operation with minimal human intervention

- Predictive maintenance for reduced downtime

- Higher productivity & cost savings

- Hybrid CNC Machining (CNC + 3D Printing) Combining CNC machining with additive manufacturing (3D printing) is reducing material waste and speeding up prototyping.

- 50% less material waste

- Faster prototyping for aerospace & defense

- Stronger, lightweight components

- Sustainable & Energy-Efficient CNC Manufacturing Governments are pushing for eco-friendly machining practices to reduce environmental impact. Sustainability Trends:

- Energy-efficient motors cutting power consumption by 20-30%

- Water-based coolants minimizing chemical waste

- Metal chip recycling lowering production costs

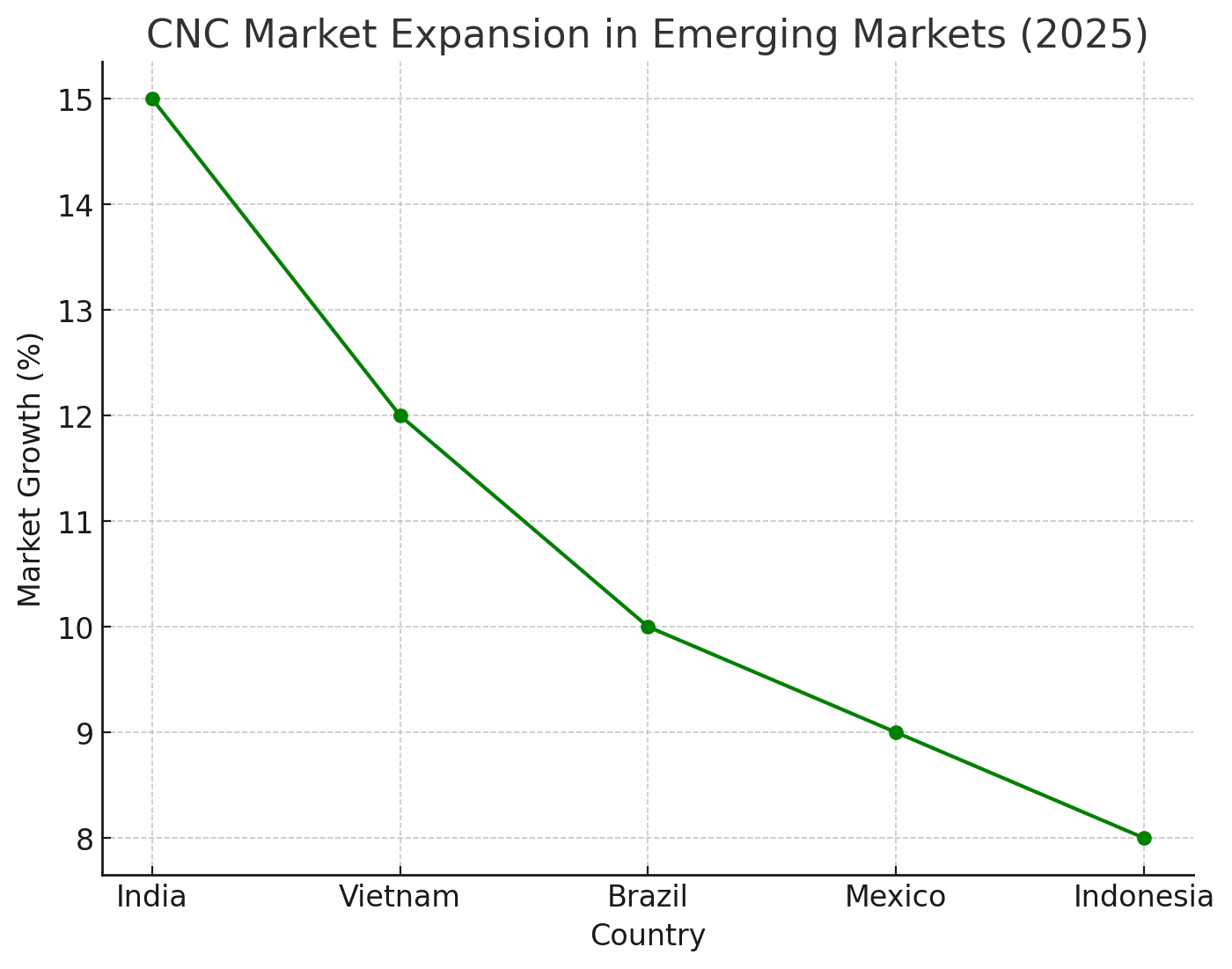

- CNC Industry Growth in Emerging Markets Countries like India, Vietnam, and Brazil are becoming global CNC hubs, fueled by government incentives and industrial expansion.

- Lower operational costs than Western markets

- Government subsidies for CNC automation

- Growing demand for precision manufacturing

- Advancements in CNC Software & Simulation AI-driven software & digital twin technology are improving CNC programming, accuracy, and real-time machine monitoring.

- AI-powered simulations reducing errors

- Cloud-based CNC software enabling remote operations

- Automated toolpath optimization boosting efficiency

Conclusion The future of CNC machining lies in automation, multi-axis machining, hybrid technology, and sustainability. Manufacturers embracing these trends will increase efficiency, reduce costs, and gain a competitive edge.

Sahil Machines is leading this transformation with high-precision CNC solutions for global industries.

- Visit us: www.sahilcnc.com

- Inquiries: info@sahilcnc.com

- Follow Sahil Machines for CNC industry updates!

Published at: March 17, 2025

Latest News

The Role of CNC Machining in Shipbuilding & Marine Engineering

How Indian CNC Manufacturers Are Expanding Globally

5-Axis CNC Machining: The Next Big Leap in Precision Engineering

The Impact of Advanced Tooling on CNC Productivity

The Role of CNC in India’s “Make in India” & Atmanirbhar Bharat Initiatives

How to Choose the Right CNC Machine for Your Industry

CNC Machining in the Defense Industry: Why It’s Essential

Growth of 5-Axis & Multi-Axis CNC Machines

The Growth of CNC Machine Exports from India Market Overview

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.