An Overview of VMC Machines : Understanding Types, Applications, and Processes

Precision, versatility, and efficiency are crucial in the modern manufacturing world. This is exactly where Vertical Machining Centers(VMC) come into play.

September 12, 2024

Share:

Precision, versatility, and efficiency are crucial in the modern manufacturing world. This is exactly where Vertical Machining Centers(VMC) come into play. From aerospace to automotive, and medical to consumer goods, VMC machines are at the heart of modern production lines, enabling manufacturers to meet the ever-increasing demands for quality and innovation. Let’s explore how VMCs revolutionize production, enhancing both quality and productivity.

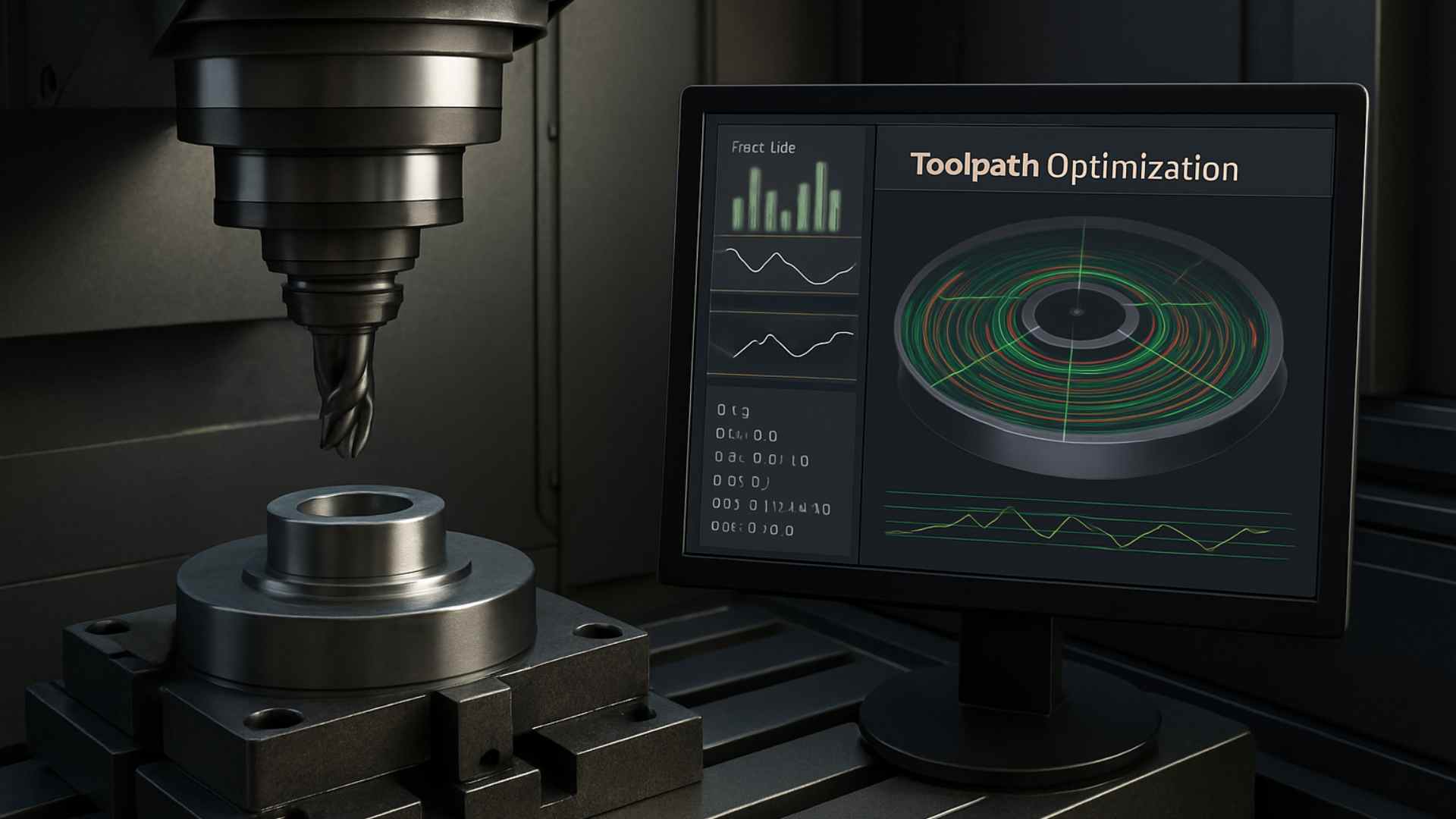

What is a Vertical Machining Center (VMC) machine?

A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in contemporary manufacturing for producing complex and intricate parts with precision, quality, and high efficiency.

Essential Principles of VMC Machines for Precision Manufacturing

Vertical Spindle Orientation: The spindle is oriented vertically, allowing for efficient material removal and high precision in machining operations.

CNC Control: Operated through Computer Numerical Control (CNC) systems, ensuring precise and repeatable movements based on programmed instructions.

Multi-Axis Movement: Typically features movement along the X, Y, and Z axes, with some models including additional rotational axes for complex machining.

High Precision: Capable of achieving tight tolerances and intricate geometries, essential for precision manufacturing.

Coolant System: Includes a coolant system to manage heat and remove chips from the cutting area, maintaining tool life and machining accuracy.

Rigid Structure: Built with a rigid and stable frame to minimize vibrations and ensure consistent machining quality.

Programmability: Allows for the creation and storage of complex machining programs, facilitating quick setup and repeatability for batch production.

Work-holding and Safety Features: Utilizes various work-holding methods and integrated with safety mechanisms like enclosures and interlocks to protect operators and ensure safe operation.

Different Types of VMC Machines

Typically VMC Machines have only three axes that move on the x, y, and z axes. To increase the benefits of VMC additional axis can be added. They are classified based on the spindle speed, bed structure, guide rail, and column structure.

Vertical Machining Center (VMC)

The VMC is a vertical milling machine with a spindle that moves up and down, enabling precise cuts in multiple directions. Its versatility and accuracy make it popular in the automotive, aerospace, and electronics industries.

Horizontal Machining Center (HMC)

It has a horizontally positioned spindle, making it ideal for heavy-duty machining. They're commonly used in the automotive and aerospace industries for milling large components.

Five-Axis Machining Center

The five-axis machining center is an advanced VMC that offers superior flexibility and precision by moving the cutting tool along five axes simultaneously. It easily achieves complex shapes and angles, making it popular in aerospace and mold-making industries.

High-Speed Machining Center

As the name suggests, it performs machining operations at significantly higher speeds than conventional machines. It leverages advanced technology to shorten cycle times while ensuring accuracy and surface finish quality. Its high speed and efficiency makes it ideal to be used i the electronics and automotive industry.

Double Column Machining Center

It has a sturdy structure with two columns supporting a horizontally moving spindle. This design enhances stability and rigidity, ideal for heavy-duty cutting of large workpieces or molds, benefiting industries like aerospace and die-making.

Well, by now you would already be well-versed on where VMC machines come into play. But let us dive deep into where and how VMC machines are used in contemporary manufacturing. Vertical Machining Center (VMC) is used in a diverse environment and has various applications. Some of them are:

Aerospace Industry

VMC machines are essential in the aerospace industry for manufacturing complex components like turbine blades and engine parts. Their advanced capabilities ensure the high accuracy and tight tolerances critical for aerospace applications.

Automotive Industry

VMC machines are widely used in the automotive industry to produce components like engine blocks, transmission parts, and brake systems. Because they can perform multiple operations in one setup, these machines streamline the manufacturing process and improve productivity.

Medical Industry

The medical industry uses VMC machines to manufacture complex devices like implants and surgical instruments. These machines enable precise machining with tight tolerances.

Electronics Industry

In the electronics industry, VMC machines manufacture circuit boards and connectors with high precision, ensuring accurate drilling of small holes and precise milling of intricate patterns on delicate materials like PCBs.

Mold and Die Industry

The mold and die industry relies on VMC machines for creating molds used in processes like injection molding and die casting, providing the precision needed for intricate cavities with tight tolerances.

To enhance your manufacturing sector, you do not look any further. Check out Sahil CNC machines for a diverse range of VMC machines as per your requirements.

For a better understanding let’s get to know more about VMC machines.

Components and working of a VMC machine

Precision and efficiency are key in a VMC machine. Here’s a quick look at the essential components:

-

The spindle is the heart of the VMC. It is responsible for rotating the cutting tool at high speeds to remove material from the workpiece.

-

A sturdy worktable securely holds the workpiece in place during machining.

-

The automated tool changer system allows for the swift swapping of cutting tools for various machining operations.

-

The control panel is the operator's hub, where they can program machining jobs, monitor progress, and make necessary adjustments.

It is usually constructed from premium cast iron or steel. It minimizes vibrations, maintains machining accuracy, and ensures stability and rigidity throughout operation.

A Vertical Machining Center (VMC) operates by utilizing a vertically oriented spindle that moves along the Z-axis, while the workpiece is typically clamped on a stationary table. The machine's cutting tools, attached to the spindle, perform precise movements controlled by computer numerical control (CNC) systems. The spindle can move vertically, while the table allows for movements along the X and Y axes. This multi-axis movement enables the VMC to execute complex machining tasks, such as milling, drilling, and tapping, with high accuracy and efficiency.

The CNC system ensures precise tool paths and speeds, optimizing the machining process for various materials and geometries.

Advantages of VMC Machines

Increased Productivity and Accuracy

VMC machines significantly boost productivity and accuracy by automating complex tasks, ensuring precise and consistent output. Their advanced technology reduces errors, speeds up production, and enhances overall efficiency, making them invaluable in modern manufacturing environments.

Automation and Speed

Automation in VMCs integrates CNC systems for precise, repeatable operations with minimal human intervention, reducing labor costs and enhancing efficiency. High-speed capabilities shorten machining times, increasing throughput. Advanced tool changers and adaptive control systems further optimizes the process.

Flexibility and Versatility

VMCs handle various materials, including metals, plastics, and composites. With multi-axis capabilities, they perform complex milling operations like contouring, drilling, tapping, threading, and pocketing, offering flexibility and versatility in machining applications.

Cost.-Effectiveness and Reduced Labour

The cost-effectiveness and reduced labour due to their automation and precision. They minimise manual intervention, enhancing efficiency and accuracy in manufacturing processes. These machines streamline production, lower operational costs, and boost productivity, making them an economical choice for businesses.

Why choose Sahil Machines' VMCs?

Choosing and selecting the right Vertical Machining Center(VMC) as per your needs is all that you want. Well, we want the same, for you to have an efficient, accurate and fast manufacturing experience.

At Sahil Machines, we ensure you receive top-quality products. Backed by years of industry experience, we offer advanced VMC machines that deliver exceptional precision, reliability, and efficiency, tailored to meet the unique demands of your operations. Sahil Machines offers customizable solutions that meet the diverse requirements of customers across industries.

VMC machines are absolutely necessary in the modern manufacturing sector to handle complex tasks with accuracy and efficiency. From aerospace to medical manufacturing requirements, we are here to help you out choose the best for your industry. Trust us to be your partner for your manufacturing needs.

FAQ

VMC machines offer high precision, versatility, and efficiency, making them ideal for complex machining tasks.

The cost of a VMC machine can vary significantly based on its size, capabilities, brand, and additional features.

VMCs offer versatility in handling various materials and complex geometries, making them essential for competitive and scalable manufacturing operations.

Factors to consider include your machining needs, part size and complexity, machine reliability, space and power requirements, budget, and long-term operational goals.

Yes, VMC machines can be customized with options such as varying spindle speeds and control systems to meet specific application requirements. Contact our team to discuss your needs and explore available customization options.

Follow Us:

Latest Posts

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.