Custom CNC Solutions: Powering Innovation for the Renewable Energy Industry

The blog explores how custom CNC (Computer Numerical Control) solutions are transforming the renewable energy manufacturing sector, breaking down into several key areas.

April 01, 2025

Share:

Introduction

The renewable energy sector is growing rapidly, driven by global sustainability targets and technological advancements. Precision engineering, particularly through custom CNC (Computer Numerical Control) solutions, is at the heart of this transformation, ensuring efficient and scalable clean energy production.

The Critical Role of CNC Manufacturing in Renewable Energy

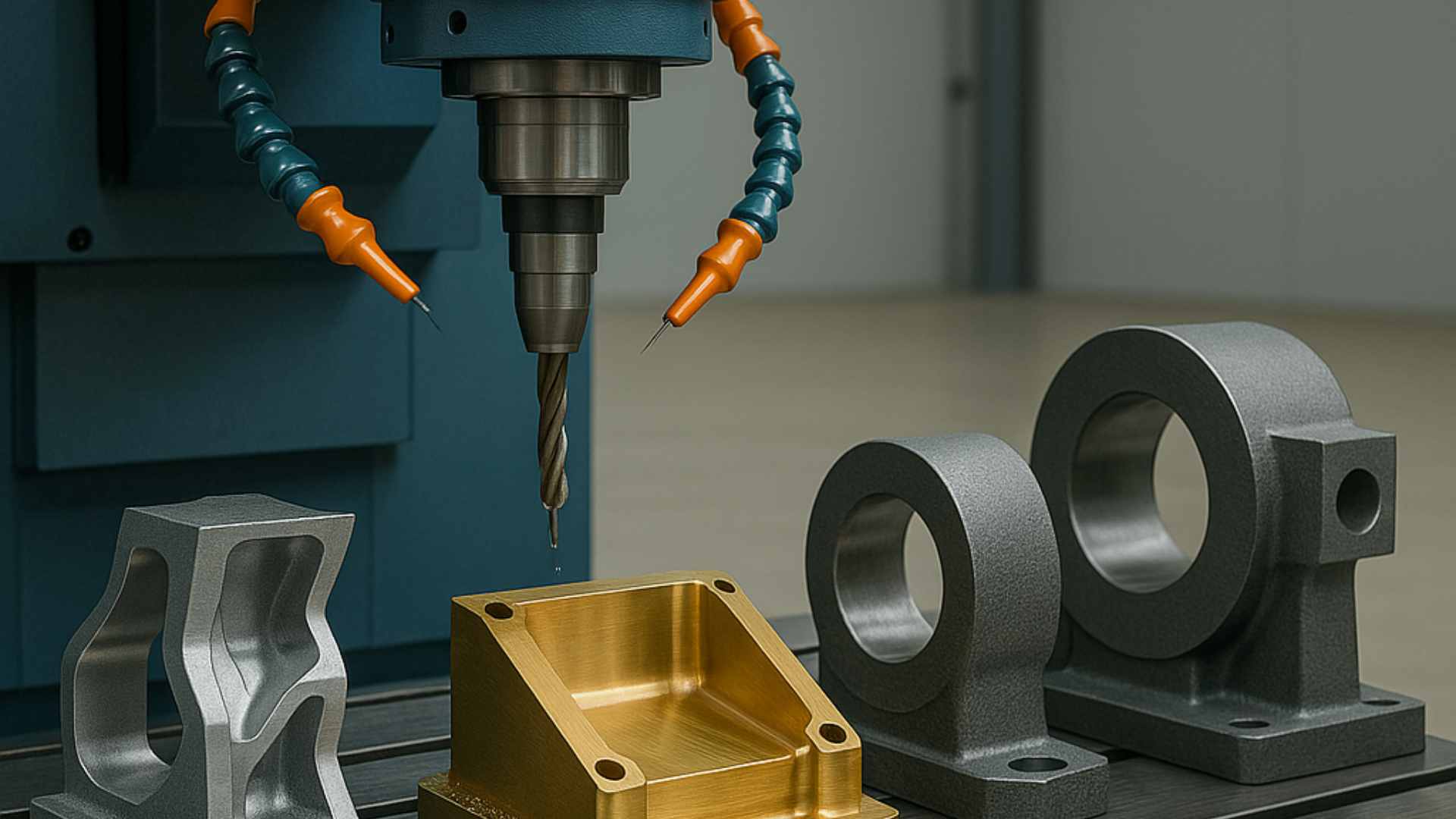

Renewable energy systems require high-precision components that are both cost-effective and scalable. Custom CNC solutions provide unmatched accuracy, repeatability, and efficiency, enabling the production of complex parts for wind turbines, solar panels, and other clean energy systems.

Key Applications

Wind Energy Manufacturing

CNC machining is essential in wind turbine manufacturing, contributing to:

- Turbine blade molds with precise aerodynamic profiles for maximum energy capture.

- High-precision gearbox components for smooth and efficient power transfer.

- Custom mounting brackets and structural supports to ensure turbine stability.

- Specialized testing equipment for quality assurance and certification.

Solar Power Applications

CNC solutions also play a crucial role in the solar energy industry by enabling:

- Custom mounting systems for panel stability and optimal sun exposure.

- Heat sink fabrication for cooling power inverters and electronics.

- Specialized tooling for solar cell production to enhance efficiency.

- Precision frames and tracking system components for accurate panel movement.

Benefits of Custom CNC Solutions

Enhanced Precision and Quality Control

Modern CNC systems, equipped with real-time monitoring and advanced sensors, ensure consistent quality in every production run. Precision is vital in renewable energy devices, where even minor deviations can impact efficiency.

Scalability and Adaptability

CNC solutions provide:

- Rapid prototyping for testing new component designs.

- Flexible production scaling based on demand fluctuations.

- Easy adaptation for different materials and evolving requirements.

- Quick implementation of design improvements without delays.

Cost-Effectiveness

Despite initial investment costs, CNC machining delivers long-term savings through:

- Reduced material waste with optimized cutting paths.

- Lower labor costs due to automation.

- Minimal error rates improving efficiency.

- Increased production capacity without sacrificing quality.

- Extended component lifespan reducing replacement costs.

Innovation and Future Trends

Advanced Materials Processing

Modern CNC systems can handle:

- Composite materials for lightweight, durable components.

- High-performance polymers enhancing longevity.

- Advanced alloys designed for extreme environmental conditions.

- Recycled materials supporting sustainable production.

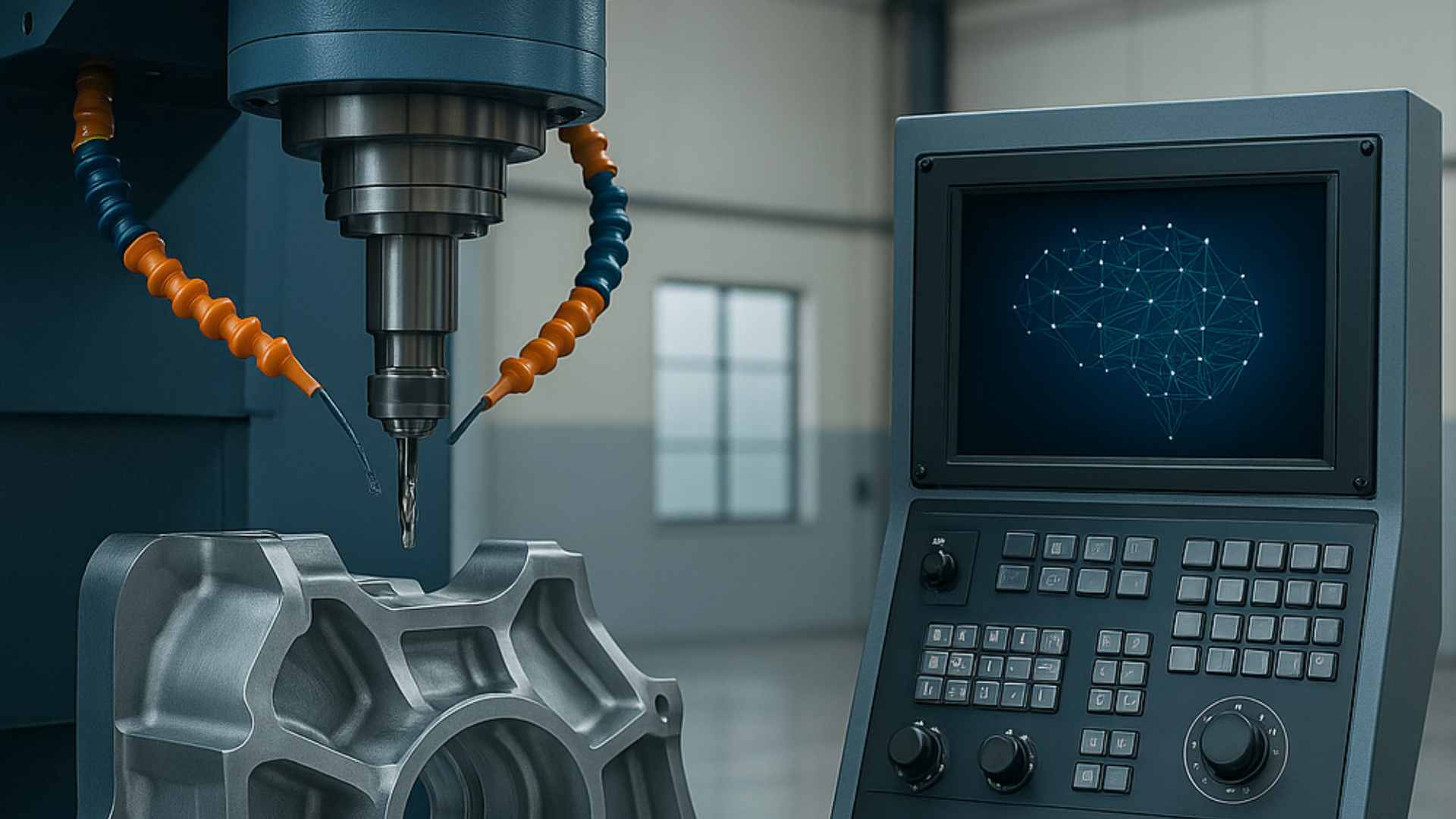

Smart Manufacturing Integration

Industry 4.0 technologies are revolutionizing CNC manufacturing, integrating:

- Real-time production monitoring and analytics for efficiency.

- Predictive maintenance reducing machine downtime.

- Automated quality control processes improving consistency.

- Digital twin technology enhancing process optimization.

Future Outlook and Opportunities

Market Expansion

As renewable energy adoption accelerates, the demand for precision CNC-manufactured components will increase, driving further technological advancements.

Technological Advancement

Future developments in CNC machining will enable:

- More complex component designs for energy efficiency.

- Faster production rates for higher output.

- Greater energy efficiency reducing operational costs.

- Enhanced automation increasing precision and reducing human intervention.

Conclusion

Custom CNC solutions are critical to the growth of renewable energy manufacturing. As the industry expands, the need for precise, scalable, and cost-effective manufacturing will continue to drive CNC innovations.

Investing in CNC technology today means optimizing current production while preparing for the future of clean energy manufacturing. From wind turbines to solar panels, CNC machining is shaping the sustainable future of global energy.

Frequently Asked Questions (FAQs)

1. How do CNC machines contribute to renewable energy manufacturing?

CNC machines provide high-precision machining for wind turbine components, solar panel structures, and power inverters, ensuring efficient energy conversion and structural durability.

2. What are the key benefits of using CNC for wind and solar energy?

CNC machining offers enhanced accuracy, reduced material waste, cost-effectiveness, and scalability, making it ideal for high-performance renewable energy components.

3. How does CNC technology improve efficiency in renewable energy production?

With real-time monitoring, automated quality control, and predictive maintenance, CNC machines boost efficiency, minimize errors, and optimize material usage in energy production.

4. What materials are commonly used in CNC machining for renewable energy?

CNC systems process composite materials, advanced alloys, high-performance polymers, and recycled materials to improve durability and sustainability in clean energy applications.

5. What are the future trends in CNC manufacturing for renewable energy?

Emerging trends include AI-driven optimization, digital twin technology, Industry 4.0 automation, and renewable energy integration, leading to greater efficiency and greener production methods.

Related Products

For more details, visit Sahil CNC Machines.

FAQ

CNC machines provide high-precision machining for wind turbine components, solar panel structures, and power inverters, ensuring efficient energy conversion and structural durability.

CNC machining offers enhanced accuracy, reduced material waste, cost-effectiveness, and scalability, making it ideal for high-performance renewable energy components.

With real-time monitoring, automated quality control, and predictive maintenance, CNC machines boost efficiency, minimize errors, and optimize material usage in energy production.

CNC systems process composite materials, advanced alloys, high-performance polymers, and recycled materials to improve durability and sustainability in clean energy applications.

Emerging trends include AI-driven optimization, digital twin technology, Industry 4.0 automation, and renewable energy integration, leading to greater efficiency and greener production methods.

Follow Us:

Latest Posts

Revolutionizing Heavy Engineering: How Sahil CNC’s Double Column Milling and VTL Machines Transformed Large-Scale Manufacturing

by Admin - April 9, 2025

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.