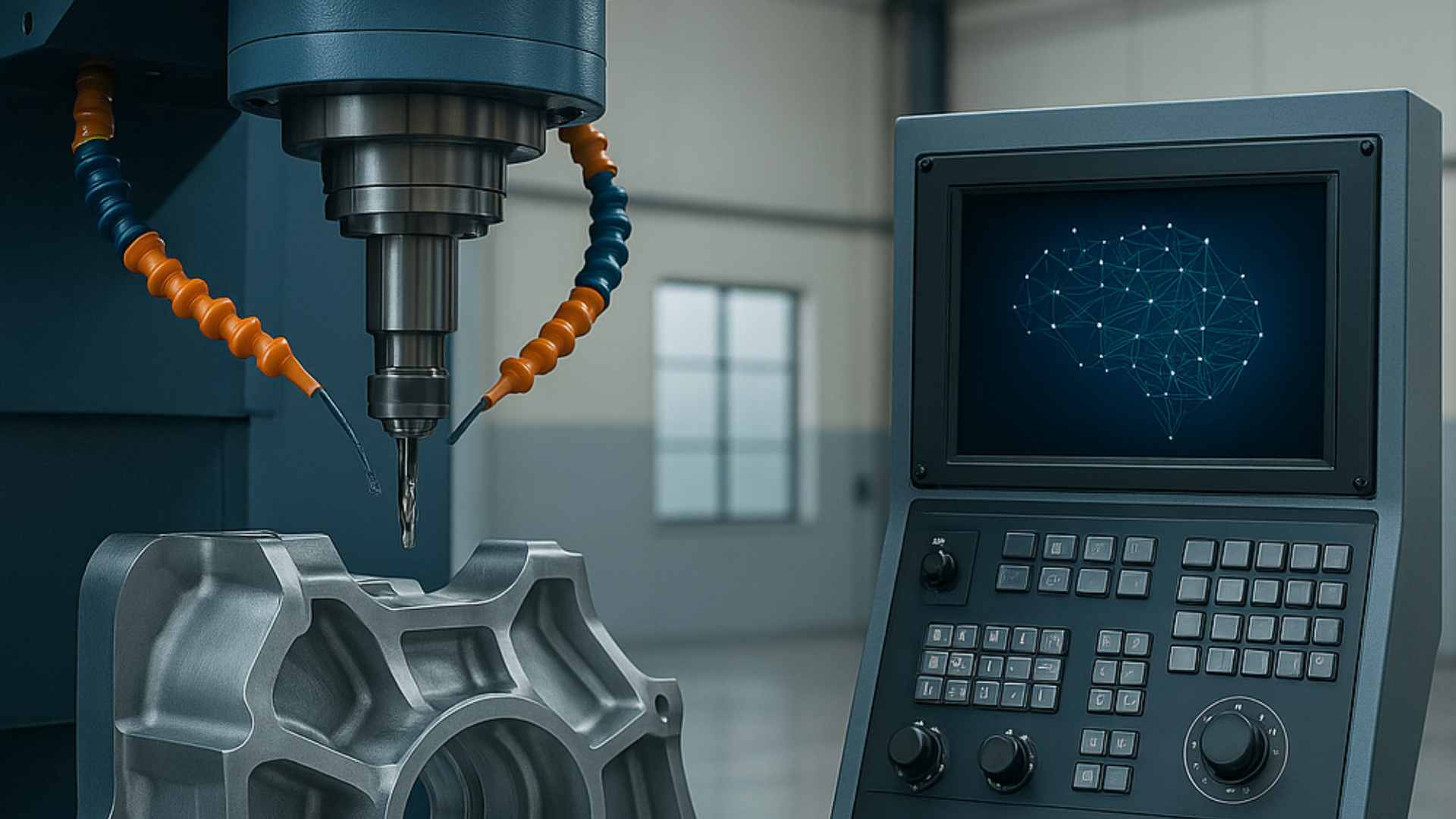

The Role of CNC Machines in Sustainable Manufacturing Practices

CNC machines are revolutionizing sustainable manufacturing by reducing material waste, conserving energy, and enhancing efficiency. With advanced technologies like digital twins, coolant recycling, and AI-driven optimizations, CNC machining is driving eco-friendly production while lowering costs and emissions.

April 01, 2025

Share:

In today’s dynamic manufacturing era, sustainability has evolved from a mere buzzword to an absolute necessity. With industries striving to reduce their environmental impact, Computer Numerical Control (CNC) machines have emerged as a game-changer in sustainable manufacturing. By combining precision, efficiency, and innovation, CNC technology helps manufacturers minimize waste, conserve energy, and reduce environmental footprints.

How Do CNC Machines Contribute to Sustainable Manufacturing?

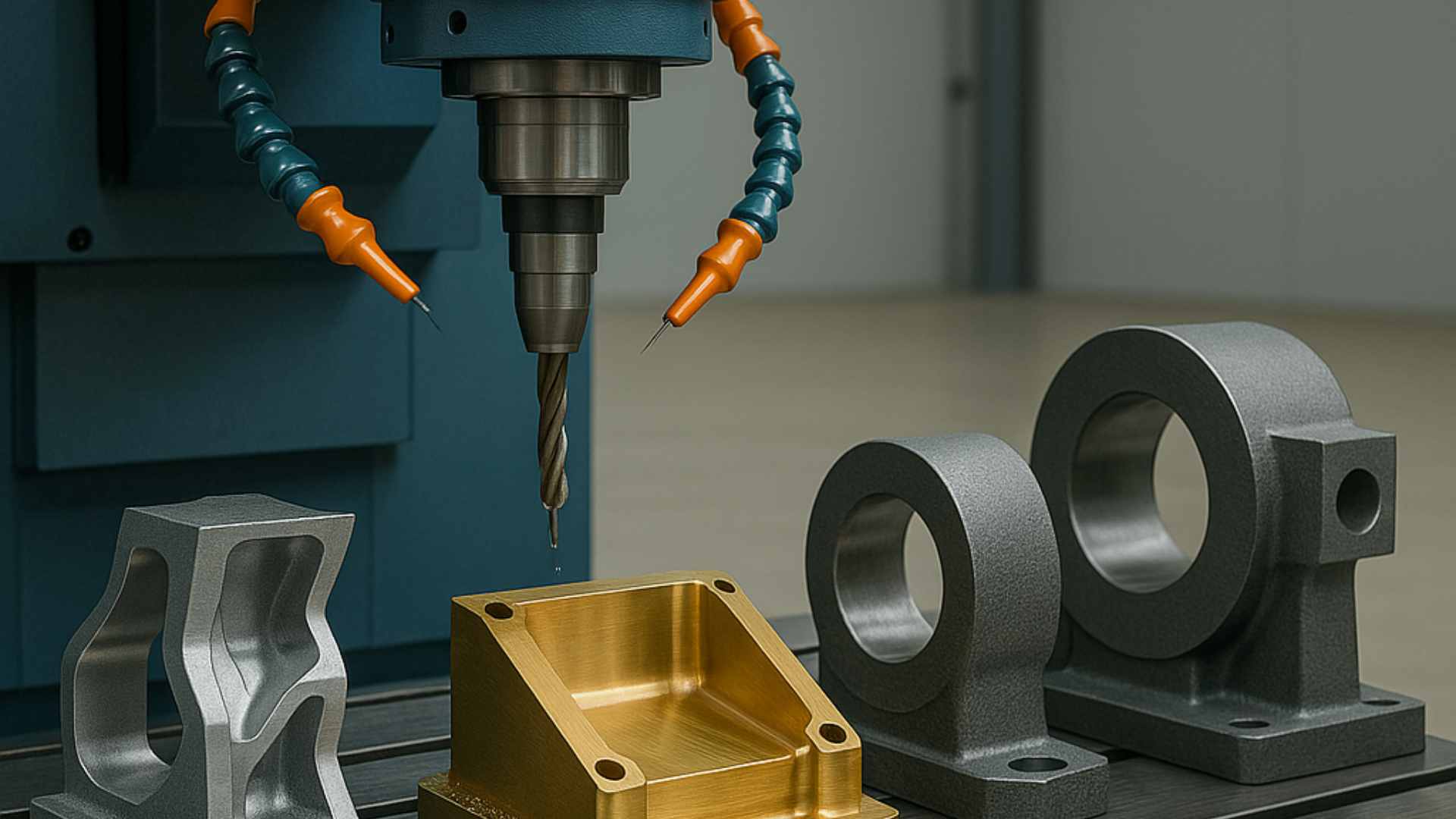

1. Minimizing Material Waste

One of the most significant contributions of CNC machines to sustainable manufacturing is reducing material waste. Unlike traditional manufacturing methods that rely heavily on manual processes, CNC machines use advanced software to optimize cutting paths, ensuring minimal scrap and offcuts.

- Precision Engineering: CNC technology allows for exact cutting, drilling, and material forming, reducing the need for rework and scrap.

- Lower Carbon Footprint: By using raw materials efficiently, manufacturers decrease extraction, processing, and disposal emissions, contributing to a greener supply chain.

2. Energy Efficiency

Modern CNC machines are built with power-saving features that lower energy consumption, making operations cost-effective while reducing their environmental impact.

- Regenerative Braking Systems: These systems capture and reuse energy generated during operation, reducing overall power consumption.

- Smart Standby Modes: CNC machines automatically switch to energy-saving modes during idle periods, cutting power consumption by up to 30% compared to older models.

3. Coolant Recovery and Water Conservation

Coolants play a vital role in CNC machining by maintaining temperature and reducing tool wear. However, improper disposal can be hazardous to the environment. CNC machines now integrate coolant recycling systems, enhancing sustainability.

- Reduced Water Usage: Recycling coolants significantly reduces water consumption, conserving this valuable resource.

- Less Hazardous Waste: Efficient coolant management reduces toxic waste, ensuring compliance with environmental safety standards.

4. Digital Twins and Simulation Tools

Digital twins and simulation software have revolutionized CNC machining, allowing manufacturers to test and refine designs virtually before cutting materials.

- Waste Elimination: Potential design flaws can be identified before physical prototyping, reducing unnecessary material wastage.

- Faster Development Cycles: Virtual modeling accelerates product development, enabling businesses to launch eco-friendly products sooner.

Key Benefits of CNC Machines for Sustainable Manufacturing

- Resource Efficiency: CNC machines maximize material, power, and water usage, aligning with circular economy principles.

- Lower Emissions: By reducing energy consumption and material wastage, CNC machines contribute to lower greenhouse gas emissions.

- Cost Savings: Sustainable CNC processes lead to lower operational costs over time.

- Innovative Design Capabilities: Advanced CNC features enable the creation of lightweight, durable, and sustainable products.

The Future of CNC Machines in Sustainable Manufacturing

With the increasing demand for sustainability, CNC technology is continuously evolving to meet greener manufacturing standards. Some emerging trends include:

- AI and Machine Learning: AI-powered CNC machines can optimize cutting paths, predict maintenance needs, and improve energy efficiency.

- Additive Manufacturing: The integration of CNC machining with 3D printing can minimize material waste and enhance sustainability.

- Renewable Energy Integration: CNC machines powered by solar, wind, or hybrid energy sources can further reduce environmental impact.

Conclusion

CNC machines are at the forefront of the sustainable manufacturing movement. By minimizing waste, conserving energy, and integrating advanced technologies, they empower industries to reduce their environmental impact without compromising productivity or efficiency.

As the shift towards sustainability accelerates, investing in modern CNC machines will be crucial for achieving long-term environmental and economic goals. Whether you're a small workshop or a large-scale manufacturing plant, adopting CNC technology is the first step toward a greener, more sustainable future.

Related Products

For more details, visit Sahil CNC Machines.

FAQ

CNC machining automates production, ensuring accurate material usage and reducing excess waste, energy consumption, and emissions compared to manual or conventional machining methods.

Automation enhances production efficiency, reduces human errors, and minimizes rework, all of which contribute to sustainable manufacturing practices.

Yes, CNC machines provide long-term cost savings, improve efficiency, reduce material waste, and align with sustainability goals, making them a smart investment.

Follow Us:

Latest Posts

Revolutionizing Heavy Engineering: How Sahil CNC’s Double Column Milling and VTL Machines Transformed Large-Scale Manufacturing

by Admin - April 9, 2025

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.