What Are Cast Iron Angle Plates? Understanding Their Role in Machining

Cast iron angle plates are essential tools in precision machining, offering stability, accuracy, and durability. They are made from high-grade cast iron with precision-ground surfaces, making them ideal for alignment, measurement, and fixture development. Their vibration-dampening and thermal stability ensure reliable performance, making them a valuable asset in manufacturing setups of all sizes.

April 01, 2025

Share:

What Are Cast Iron Angle Plates?

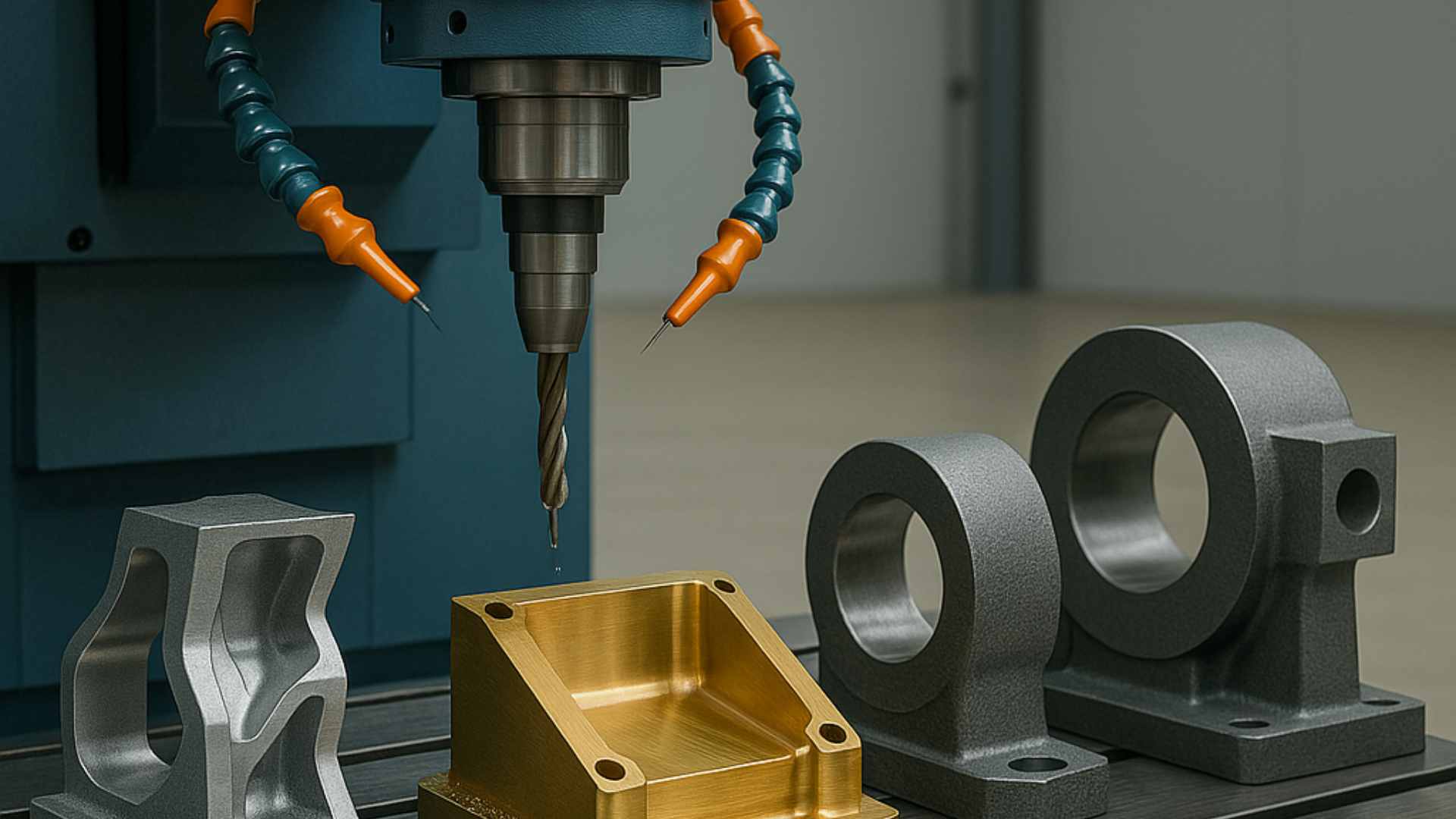

Cast iron angle plates have a very simple yet effective design. They are manufactured from high-grade cast iron and feature an L-shaped design with a right-angle or 90-degree machining surface. The stability and accuracy offered by cast iron angle plates make them an irreplaceable tool in the manufacturing industry.

Functions of Cast Iron Angle Plates

The effectiveness of cast iron angle plates lies in their unique characteristics, including:

- Precision-ground surfaces: Ensure exceptional flatness and perfectly perpendicular faces are maintained to the strictest tolerances.

- Robust construction: Allows them to support substantial loads.

- Stress-relieved cast iron material: Provides long-term stability.

- Versatility: Increased with a variety of mounting options due to precisely machined slots and holes.

Benefits of Using Cast Iron Angle Plates

Cast iron angle plates are primarily used as alignment tools but offer versatility for many other machining tasks. Here are their key benefits:

Orientation and Stability

Their perpendicular (90°) working surface makes workpiece alignment feasible, ensuring every cut, drill, or measurement is perfect. The stability offered further enhances their function.

Quality and Accuracy

They serve as excellent tools for measuring components and checking geometrical accuracy, which is crucial for manufacturing sectors working with high tolerances.

Fixture Development

They provide the perfect base for designing fixtures with steadfastness and accuracy. Special fixtures for cast iron angle plates are available for custom machining operations.

The Role of Cast Iron Angle Plates in Machining

Cast iron angle plates offer numerous advantages, including:

Vibration Dampening

The natural dampening properties of cast iron reduce machining vibrations, improving surface finish and tool life. This is vital in high-precision operations.

Thermal Stability

Their excellent thermal stability ensures consistent performance even in workshops with variable temperatures.

Durability and Longevity

With proper care, cast iron angle plates can last for years. Their resistance to wear and structural stability make them a worthwhile investment for any precision engineering facility.

Selecting the Right Angle Plate

Choosing the right cast iron angle plate can be challenging. At Sahil Machines, we ensure you receive top-quality products tailored to your needs. Here are the key factors to consider:

Size

The plate should be proportional to the workpiece and machining equipment. Oversized plates waste space, while undersized plates can compromise stability.

Accuracy Requirements

Different applications have different accuracy requirements. Select plates with the appropriate grades of accuracy.

Maintenance

Store cast iron angle plates in a controlled environment to prevent rust or corrosion. Clean them periodically and apply protective coatings.

Add-Ons

Consider additional features like T-slots, mounting holes, and reinforcing ribs. While these enhance versatility, ensure they align with your application needs.

Future Trends and Developments

The manufacturing industry continues to innovate. Key trends include:

- Lightweight designs without compromising strength.

- Advanced material compositions for improved stability.

- Digital measurement integrations.

- Enhanced surface treatments for better wear resistance.

Conclusion

Cast iron angle plates remain indispensable in precision machining. They offer immense stability, accuracy, and versatility, making them a perfect mix for modern manufacturing needs. Whether it's routine alignment tasks or complex precision measurements, understanding and maintaining these tools can greatly impact machining quality.

At Sahil Machines, we combine years of industry experience to deliver advanced CNC machines and solutions designed for precision, reliability, and efficiency. Explore our product range to enhance your manufacturing setup.

FAQ

They provide precision and stability, making them a reliable long-term investment for machining and inspection.

Yes, they offer durability, withstand heavy use, and maintain accuracy, ensuring a high return on investment.

Yes, they are available in various accuracy grades, such as Grade 0 or Grade 1, depending on the application.

Cast iron angle plates have excellent thermal stability, ensuring consistent accuracy in changing workshop conditions.

Yes, they come in different sizes and configurations, making them ideal for both large industrial setups and small workshops.

Follow Us:

Latest Posts

Revolutionizing Heavy Engineering: How Sahil CNC’s Double Column Milling and VTL Machines Transformed Large-Scale Manufacturing

by Admin - April 9, 2025

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.