Heavy-Duty Turning Lathes: An Essential Component in Modern Manufacturing

A heavy-duty turning lathe is precision machinery for machining large components in the aerospace, automotive, and energy industries. Offering efficiency, durability, and advanced technology, it handles tasks like turning, boring, and threading with high accuracy.

April 01, 2025

Share:

Heavy-duty turning lathes are an extremely essential part of the manufacturing landscape. From the aerospace industry to shipbuilding, manufacturing heavy components with utmost precision and efficiency is key. This is exactly where a heavy-duty turning lathe comes in as a savior. Dive in to know the benefits, types, and key insights of a heavy-duty turning lathe.

What are Heavy-Duty Turning Lathes?

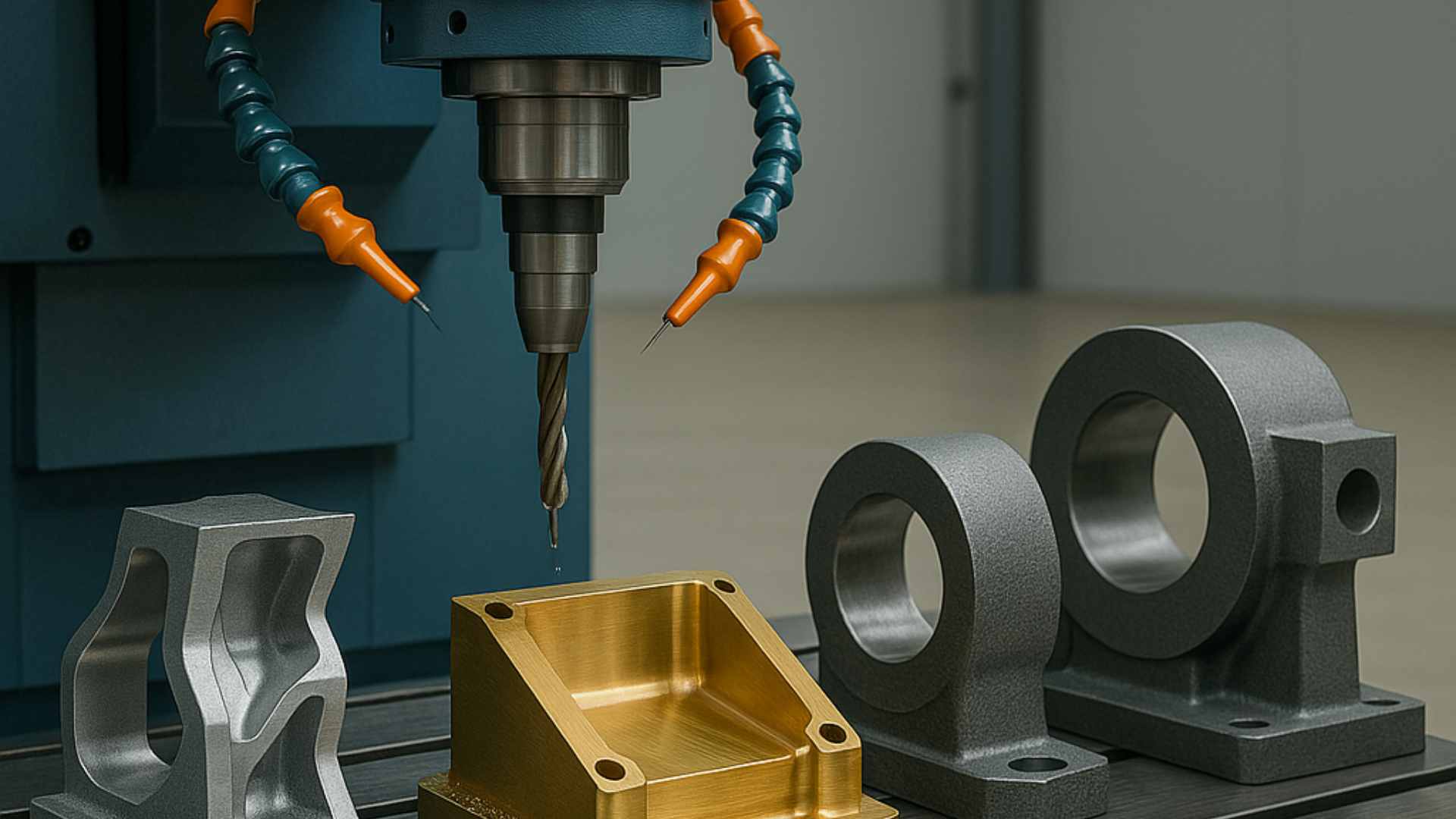

A heavy-duty turning lathe is specialized machinery designed to handle heavy components and workpieces. The workpieces are rotated against cutting tools to perform various tasks like turning, boring, and threading.

Well, what sets these machines apart? Their ability to handle heavy workpieces without compromising on precision and specifications.

Types of Heavy-Duty Turning Lathes

Heavy-duty turning lathes come in different variants for different industrial needs. They are roughly classified into:

- Horizontal Heavy-Duty Lathes: Designed to handle extended and heavy workpieces, mainly used to manufacture shafts and pipes.

- Vertical Heavy-Duty Lathes: Designed for shorter and wider workpieces, used to manufacture flanges and gear blanks.

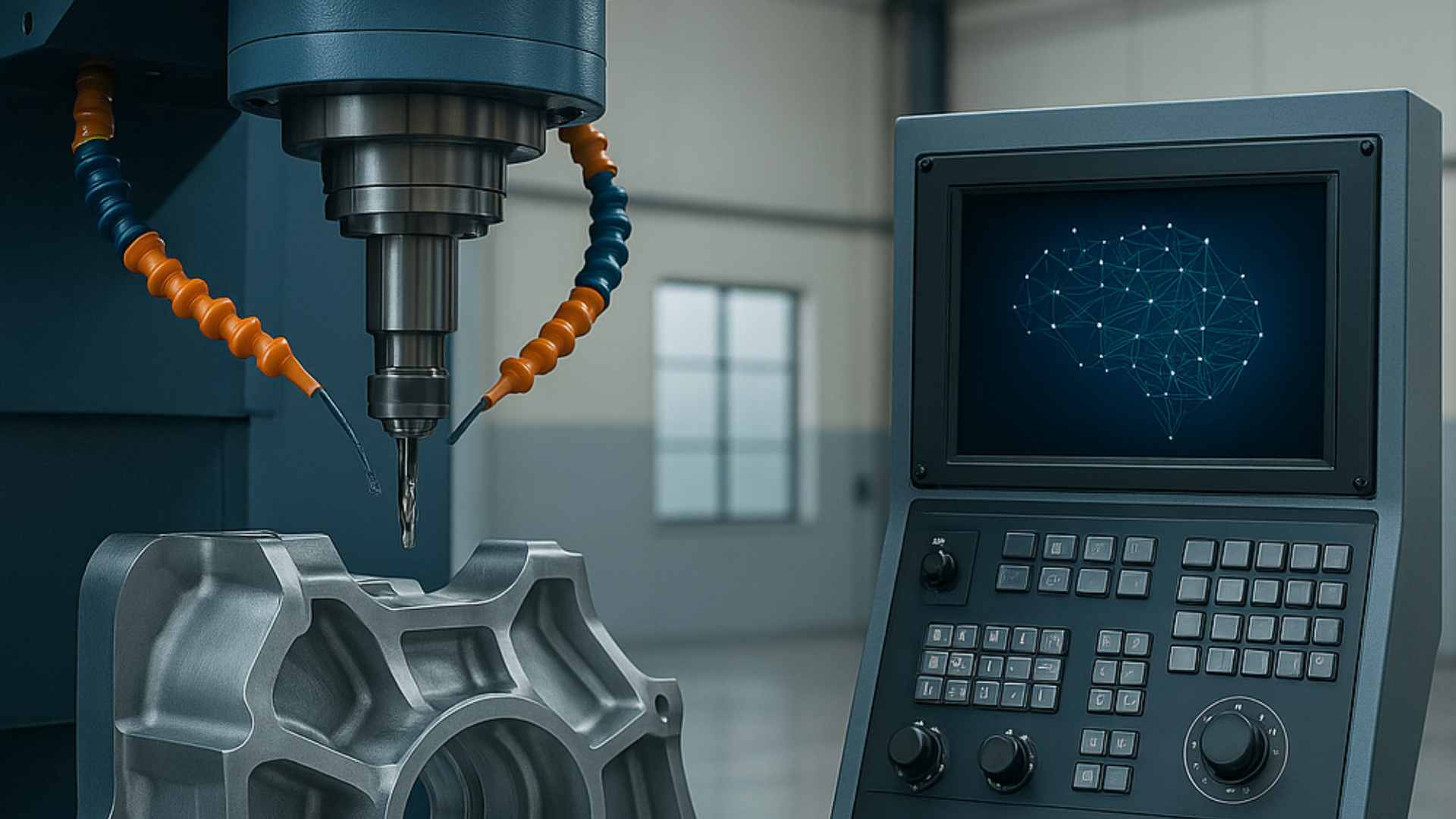

- CNC Heavy-Duty Lathes: Incorporate Computer Numerical Control (CNC) and automation in manufacturing, offering unmatched precision and accuracy.

Key Components of Heavy-Duty Turning Lathes

Understanding the components of a heavy-duty turning lathe is crucial for proper operation and maintenance. Key components include:

- Bed: A great foundation that provides stability and support to heavy workpieces.

- Headstock: A sturdy component that houses the spindle and critical driving mechanisms.

- Tailstock: A support system for workpieces during machining, ensuring stability and accuracy.

- Carriage: Precisely moves the cutting tool along the workpiece.

- Chuck: Secures the workpiece in place while the task smoothly happens.

- Control System: In CNC models, the control system automates and controls the machining process.

Benefits of Using Heavy-Duty Turning Lathes

A heavy-duty turning lathe is designed to handle large workpieces and harder materials.

Precision and Quality

These machines are integrated with CNC for higher precision and high-quality finishes.

Efficiency and Speed

These machines perform multiple operations such as turning, facing, and threading all in a single setup with high speed, further reducing production time.

Versatility and Durability

These machines can withstand extreme conditions and produce large components with a wide range of materials. They operate on minimum vibrations even during heavy machining.

Common Applications of Heavy-Duty Turning Lathes

Heavy-duty turning lathes are used widely across various industries requiring heavy and large components.

- Aerospace: Crafting critical engine components and structural elements.

- Automotive: Manufacturing vital elements like crankshafts, axles, and other critical parts.

- Energy: Precise and accurate machining of turbine parts and large-diameter pipes.

- Shipbuilding: Creating massive components like propeller shafts and marine engine parts.

Choosing the right machine for your industry can be challenging. That is exactly why we are here to help.

Well, we want you to have an efficient and fast manufacturing experience. At Sahil Machines, we ensure you receive top-quality products. Backed by years of industry experience, we offer advanced CNC machines that deliver exceptional precision, reliability, and efficiency, designed to meet the unique demands of your operations. Sahil Machines offers customizable solutions that meet the diverse requirements of customers across industries. Check out our product range.

Here are a few more insights that can be helpful for you.

Operating a Heavy-Duty Turning Lathe

Operating a heavy-duty turning lathe requires expertise, and following a few guidelines makes it easier and safer to operate. A few of them are:

- Securing the workpiece and operating tools.

- Setting accurate cutting parameters.

- Regularly monitoring the machine as tasks are carried on.

Safety and Maintenance

Safety is key while handling heavy machinery and should never be compromised.

- Follow standard operating procedures and training.

- Wear appropriate protective gear and equipment.

- Use safety guards and emergency stops whenever necessary.

Regular maintenance ensures the performance and longevity of heavy-duty turning lathes.

- Lubrication of moving parts regularly.

- Continuous inspection of electrical systems for faults.

- Checking for wear and tear regularly and immediate repairs and fixing.

Future Trends in Heavy-Duty Turning Technology

The development of heavy-duty turning lathes is continuous with some exciting technological advancements:

- Smart Manufacturing: Embedding IoT and AI-driven features such as predictive maintenance and real-time monitoring that reduce downtime and ensure that machines work to optimize performance.

- Enhanced Automation Systems: Incorporation of robotics into enhanced automation systems has risen, ensuring much higher efficiency and consistency in most manufacturing processes.

- Sustainable Design Approaches: Newer models emphasizing energy efficiency and environmental consciousness.

Conclusion

Heavy-duty turning lathes are necessary for any industry where high-precision machining of large components is needed. Knowing and doing your research about it maximizes the efficiency and productivity of your business. As technology evolves, so will these machines play a critical role in modern manufacturing. Whether an industry professional or an enthusiast, stay updated and make the most of it.

At Sahil Machines, we specialize in providing advanced heavy-duty turning lathes tailored to meet diverse industrial needs. Whether you're looking for Heavy-Duty Lathes, Floor Plates, or Vertical Lathes, our product range ensures precision, durability, and efficiency.

Visit our Industries We Serve page to see how our machines are used in sectors like aerospace, automotive, and energy. For guidance on maintenance, check out our Machine Guides.

Stay updated with the latest industry trends on our Blog.

Have questions? Feel free to reach out via our Contact Us page. We're here to help!

FAQ

Consider the size and weight capacity of the machine, power and speed capabilities, CNC or manual operation, required precision, and safety features.

Heavy-duty lathes are built to handle larger and heavier workpieces, ensuring greater stability and precision during intense machining operations.

Yes, they are cost-effective in the long run due to their durability, efficiency, and ability to handle demanding projects with minimal waste.

CNC lathes are ideal for precision and automation, especially for complex or repetitive tasks, while manual lathes are better for simpler operations or if budget is a concern.

These lathes can work with various materials, including metals like steel, titanium, and aluminum, as well as composites and other hard materials.

Follow Us:

Latest Posts

Revolutionizing Heavy Engineering: How Sahil CNC’s Double Column Milling and VTL Machines Transformed Large-Scale Manufacturing

by Admin - April 9, 2025

Get in touch with us about anything.

Connect with our team to explore the alloy solutions and machinery expertise you need.